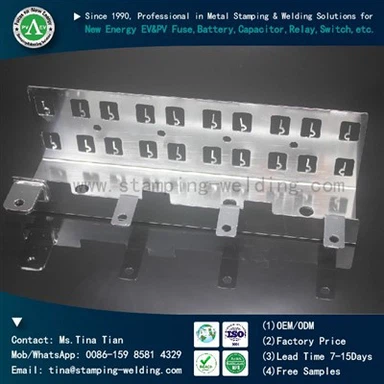

DC Link EV Film Capacitor Busbar

Designed with precision and tailored to the specific requirements of modern EVs, the DC Link EV Film Capacitor Busbar offers a compact and efficient solution for managing the energy flow within the vehicle's power electronics system. This introduction aims to provide a glimpse into the significance and functionality of the DC Link EV Film Capacitor Busbar, showcasing its role in enhancing the performance, efficiency, and overall sustainability of electric vehicles.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Products Description

The DC Link EV Film Capacitor Busbar stands at the forefront of innovation in electric vehicle (EV) technology, playing a pivotal role in ensuring optimal performance and reliability. As electric vehicles continue to revolutionize the automotive industry, the demand for advanced and efficient energy storage solutions has never been higher. The DC Link EV Film Capacitor Busbar addresses this need by serving as a crucial component within the DC link of electric vehicles, facilitating the seamless transfer of energy between the energy storage system and the inverter.

features of DC Link EV film Capacitor Busbar

- Compact and Space-Efficient

The DC Link EV Film Capacitor Busbar is designed with a compact form factor, optimizing space utilization within the electric vehicle. Its space-efficient design is crucial for the constrained environments often found in electric vehicles.

- High Power Density

With a focus on maximizing power density, this capacitor busbar delivers high performance within a relatively small footprint. It is engineered to handle the demanding power requirements of electric vehicles efficiently.

- Low Inductance

The DC Link EV Film Capacitor Busbar is engineered with low inductance characteristics, minimizing energy losses and ensuring rapid energy transfer within the DC link. This feature contributes to the overall efficiency of the electric vehicle's power electronics system.

- Enhanced Thermal Management

To address the heat dissipation challenges in electric vehicles, the DC Link EV Film Capacitor Busbar incorporates advanced thermal management features. This ensures optimal performance even under demanding operating conditions.

- High Voltage Rating

Designed to meet the high voltage demands of electric vehicle systems, the DC Link EV Film Capacitor Busbar offers a robust and reliable solution for handling elevated voltage levels within the DC link.

- Customizable Configurations

Recognizing the diverse requirements of electric vehicle designs, the DC Link EV Film Capacitor Busbar supports customizable configurations. This adaptability allows it to be seamlessly integrated into various EV architectures.

- Long Service Life

Built with durability in mind, the capacitor busbar is engineered to withstand the rigorous conditions of electric vehicle operation. Its longevity contributes to the overall reliability and sustainability of the EV system.

- Low ESR (Equivalent Series Resistance)

The DC Link EV Film Capacitor Busbar features low ESR, minimizing energy losses and ensuring efficient energy storage and release. This low resistance contributes to the high efficiency of the electric vehicle's power electronics.

Our Advanced Technology

- Precision Laser Cutting

Our machinery employs precision laser cutting technology, allowing for the accurate shaping and cutting of materials used in the DC Link EV Film Capacitor Busbar. This ensures that each component is precisely crafted to meet design specifications.

- Automated Material Handling

Automated material handling systems streamline the production process by efficiently managing the movement and positioning of materials. This automation enhances efficiency, reduces errors, and ensures consistent quality.

- High-Speed Punching and Forming

High-speed punching and forming capabilities enable rapid production of the capacitor busbar components. This not only enhances efficiency but also ensures that production can meet the demands of a dynamic electric vehicle market.

- Advanced Welding Technology

Our machinery utilizes advanced welding technology to ensure strong and reliable connections between different components of the DC Link EV Film Capacitor Busbar. This contributes to the durability and performance of the final product.

- Automated Assembly Systems

Automated assembly systems play a crucial role in putting together the various elements of the DC Link EV Film Capacitor Busbar. This automation guarantees consistency in assembly, reducing the likelihood of errors and enhancing overall product quality.

- In-Line Quality Control

Our manufacturing process includes in-line quality control measures that monitor and verify the quality of components at different stages of production. This proactive approach ensures that any issues are identified and addressed promptly.

- Advanced Testing and Inspection

Our machinery is equipped with advanced testing and inspection tools to assess the performance and reliability of the DC Link EV Film Capacitor Busbar. This includes electrical testing, thermal testing, and other evaluations to guarantee adherence to specifications.

- Customization Capabilities

The flexibility of our advanced machinery allows for the customization of DC Link EV Film Capacitor Busbars to meet specific client requirements. This ensures that our products seamlessly integrate into diverse electric vehicle systems.

- Data-Driven Manufacturing

Our manufacturing processes are data-driven, leveraging real-time monitoring and analytics. This data-centric approach enables us to optimize production efficiency, identify areas for improvement, and consistently deliver high-quality products.

- Environmental Consideration

Our machinery is designed with environmental sustainability in mind. We prioritize energy efficiency and waste reduction, aligning our manufacturing practices with eco-friendly principles.

Contact Us

Hot Tags: dc link ev film capacitor busbar, China, manufacturers, suppliers, factory, Copper Pipe End Cap And Fuze Terminal, Outer Cap And Automotive Fuse Terminals, Knife Fuse Holder, Inner Cap With Hole For Fuse Base, Copper Outer Cap And Terminal For Fast Fuse, Caps For Fuse Holders