Photovoltaic System Fuse Copper Contact

With the global emphasis on renewable energy and the popularity of photovoltaic power generation systems, the market demand for photovoltaic power generation equipment and accessories continues to grow. As one of the important protection components in photovoltaic power generation systems, the market demand for fuse copper contacts has also increased.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

PRODUCT DESCRIPTION

Photovoltaic system fuse copper contact is usually made of high-quality pure copper material. Because of its excellent electrical conductivity, corrosion resistance, wear resistance, and good thermal conductivity, it is suitable for long-term stable operation in photovoltaic power generation systems.

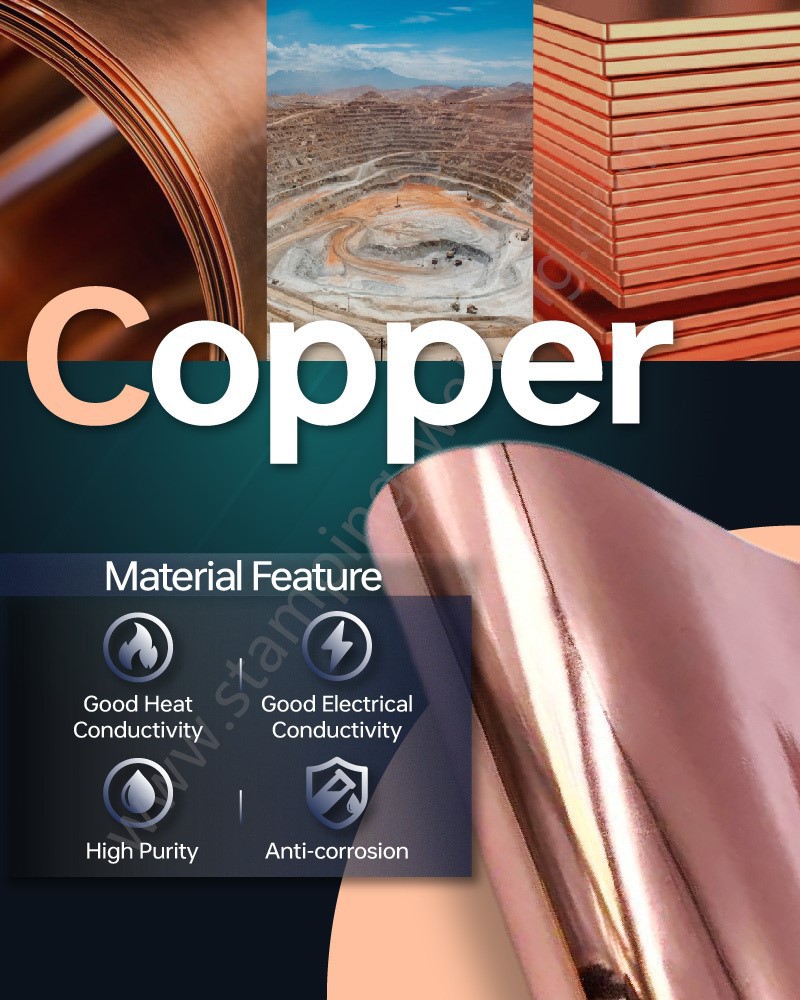

MATERIAL PROPERTIES

Good recyclability: Copper is a recyclable metal material. Through recycling and reuse, it can save resources, reduce energy consumption, and is conducive to environmental protection and sustainable development.

Excellent electrical conductivity: Pure copper material has good electrical conductivity and can effectively transmit current.

Corrosion resistance: Copper has certain corrosion resistance and is suitable for use in humid environments.

Wear Resistance: Copper is precision machined to have a smooth surface, wear resistance and long service life.

Good thermal conductivity: Copper material has good thermal conductivity and can effectively dissipate heat and maintain stable operation of the equipment.

PRODUCT ADVANTAGE

- Safe and reliable: As one of the key components of the photovoltaic power generation system, the photovoltaic system fuse copper contact can quickly cut off the circuit and protect the safe operation of the circuit.

- Durable and stable: Made of high-quality copper material, it has good corrosion resistance and wear resistance, and has a long service life.

- Precision processing: Photovoltaic system fuse copper contact is manufactured through precision processing, with precise dimensions and strong adaptability, which can ensure the stability and reliability of the equipment.

PRODUCT PROCESSING

- Raw material preparation: Select high-quality pure copper materials for raw material preparation and processing.

- Stamping: Use stamping equipment to shape the copper material into the shape of the copper contact blade of the fuse.

- Welding: Use advanced welding technology to firmly weld the contact knife components.

- Processing surface treatment: Surface treatment is performed on the formed copper contact knife to improve its corrosion resistance and appearance quality.

- Quality inspection: Conduct quality inspection on the processed copper contact knives to ensure that the product meets the design requirements and standards.

TECHNICAL ADVANTAGES

Advanced equipment: The production line adopts advanced stamping equipment and processing technology to ensure accurate product dimensions and stable quality.

Strict quality control: In strict accordance with the requirements of the ISO quality management system, quality control of the production process is carried out to ensure reliable product quality.

Technical team: We have a professional technical team with rich production experience and technical strength, able to provide technical support and solutions for products.

PACKAGING AND TRANSPORTATION

Photovoltaic system fuse copper contact usually uses waterproof and shockproof packaging to ensure that the product is not damaged during transportation. The transportation method can be selected according to customer needs, and common ones include land transportation, sea transportation, and air transportation.

CONTACT US

We are committed to providing consumers with excellent photovoltaic system fuse copper contacts. The contact knives we produce can provide reliable and safe protection for your equipment. If you have any further questions or needs, please feel free to contact us and we will be happy to serve you.

To check whether the photovoltaic system fuse copper contact is in normal use, you can take the following steps: appearance inspection, conductivity test, contact inspection, temperature inspection, functional test, and professional inspection. Through these inspections, a preliminary assessment of the normal use status of the fuse copper cap can be made. If any abnormalities or problems are found, they should be replaced or repaired in time to ensure the safe and stable operation of the photovoltaic power generation system.

Hot Tags: photovoltaic system fuse copper contact, China, manufacturers, suppliers, factory, Fuse Contact Knife Cap For Electric Vehicle, Fusible End Cap And Contact For New Energy Car, Fuse Copper Outer End Cap Without Hole, Fuse Copper T2Y2 Bases, Terminal Contact, Cylindrical Body Contact Knife For Fuse Links