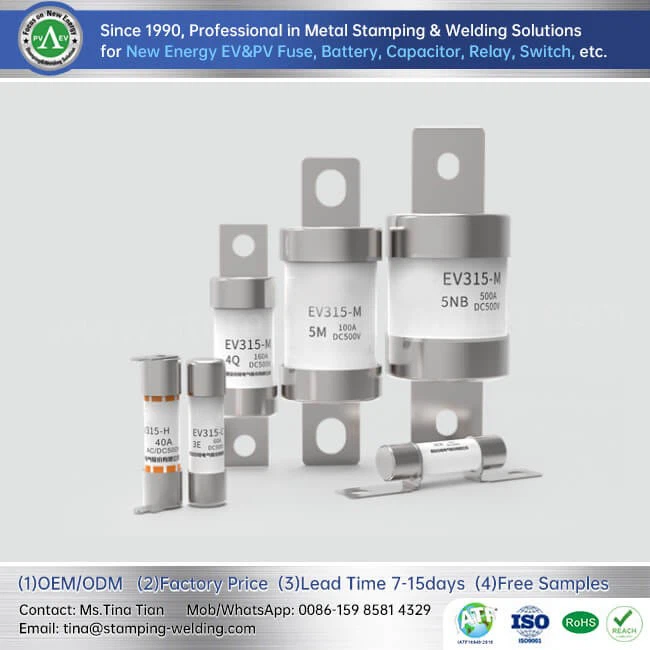

EV Fuse Copper Contact Cap

The Fuse Copper End Caps and Fuse Copper Contacts are made of the Pure Copper, Xiamen Apollo is using the Copper Stamping technology to produce the Fuse Outer End Cap and Fuse Copper Terminal, sording the Fuse Cap and Contact together.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1-Products Name: EV Fuse Copper Contact Cap

2-Base Material:

(1) Red Copper Stamping Parts: 99.99% Copper T2Y2(SECu/C1100), %IACS≥97, HV: 80~110s;

(2) Brass Stamping Parts: 65% Brass H65 (CuZn36/C2700), tensile strengthσb MPa≥440

3-Surface Treatments:

(1) Silver plating

(2) Bright tin plating

(3) Lead-free fog tin plating

(4) Nickel plating

(5) Ultrasonic cleaning

4-Technology Processes:

(1) Stamping

(2) Stretching

(3) Riveting

(4) Plating

(5) Tin Brazing

(6) Silver Brazing

(7) Laser Welding

(8) Resistance Welding

5-Free Samples: 10-50pcs is allowed

6-Lead Time: Orders 7-10days, Samples 20-25days (including the tooling/die production of Copper Stamped Part);

7-Packing: Plastic inside and carton/pallet outside

8-Certifications: ISO9001, IATF16949, RoHS, REACH, etc.

9-Production Capacity: 50,000,000 pcs/month

10-Applications: PV Fuse, EV Fuse, PDU Fuse, Energy Storage Fuse, UPS DC Links, NH Fuse, BS Fuse, Fast Fuse, etc.

Production Process of New Energy Fuse Copper Cap and Copper Contact

1- Stamping Process

(1.1)Material Preparation:

High-quality copper material is used to ensure it meets production requirements and product standards.

The copper material for Fuse Copper Cap, Fuse Copper Contact, and Fuse Copper Terminal must meet specific chemical composition and mechanical performance requirements.

(1.2)Mold Design and Manufacturing:

Design and manufacture stamping dies according to product design requirements.

The molds should have high precision and stability to ensure the production of caps and contacts that meet dimensional requirements.

(1.3)Stamping Forming:

Place the copper material on the press and form it using the molds.

Stamp the Fuse Copper Cap to create a cap structure suitable for the fuse.

Stamp the Fuse Copper Contact to create a conductive contact structure.

(1.4)Positioning and Inspection:

Ensure accurate mold positioning during stamping to avoid dimensional deviations or shape distortion.

Inspect the stamped caps and contacts for dimensions and appearance to ensure their quality meets requirements.

2-Soldering Process

(2.1)Preparation:

Prepare soldering equipment, including soldering furnace, soldering table, solder wire, etc.

Additional preparation of soldering materials is required for the production of Fuse Copper Terminal.

(2.2)Surface Treatment:

Clean the surfaces of caps, contacts, and terminals to ensure no oil, oxide, or other impurities are present.

Polish the caps and contacts to improve the surface flatness and cleanliness for soldering.

(2.3)Soldering Operation:

Position the Fuse Copper Terminal at the specific location on the cap and fix it using solder.

Ensure proper temperature and soldering time control during the soldering process to prevent overheating or inadequate soldering.

(2.4)Quality Control:

Inspect the appearance and soldering strength of the soldered components to ensure soldering quality meets standard requirements.

Promptly adjust and address any issues that arise during the soldering process to ensure product quality and stability.

Contact Information:

Ms.Tina Tian (Sales Manager&Technology Engineer)

Xiamen Apollo Stamping Welding Technology Co., Ltd

Apollo Electronic Components (Xiamen) Co.,Ltd

Add: No.2, Chengyi North Road, Jimei Software Park, Jimei District, Xiamen City, Fujian Province, China, 361022

Mob/WhatsApp/WeChat: 0086-15985814329

Email: tina@stamping-welding.com

Web: www.stamping-welding.com , www.china-electronic-components.com

Since 2010, professional in Metal Stamping & Welding Solutions for New Energy EV & PV Fuse, Battery, Capactior, Relay, Switch, ect!

The production process for the copper cap and copper contact of the new energy fuse involves the following key steps:

Material preparation: Select high-quality copper materials as raw materials for manufacturing the cap and contact.

Processing and forming: Use stamping technology to process the copper materials into the initial shape of the cap and contact.

Precision machining: Employ CNC machining equipment to precision-machine the cap and contact, ensuring dimensional accuracy and surface quality.

Surface treatment: Perform surface treatments such as polishing, sandblasting, or electroplating on the cap and contact to improve their appearance and corrosion resistance.

Assembly: Assemble the cap and contact with other fuse components to ensure proper fit and compliance with design requirements.

Through these production processes, high-performance and reliable new energy fuse caps and contacts can be efficiently manufactured.

Hot Tags: ev fuse copper contact cap, China, manufacturers, suppliers, factory, Outer Cap And Automotive Fuse Terminals, Fuse Cap, L Type Fuse Terminal, Fuse Contact And End Caps Components, Copper Pipe End Cap And Fuze Terminal, NH Fuse Knife