Understanding The Basics Of Ceramic Tube For High Voltage Fuse

Jun 26, 2025

Ceramic Tube For High Voltage Fuse are specialized protective devices engineered for high voltage electrical systems. The core of these fuses is the tube, which is crafted from high-quality insulating electrical steatite ceramic. This material is renowned for its exceptional insulating properties, mechanical strength, and thermal stability. The Ceramic Casing for Fuse Link houses the fusing element, which is designed to melt rapidly when an overcurrent or short circuit fault occurs, thereby interrupting the electrical circuit and protecting downstream components from damage.

In the realm of electrical systems, safeguarding against overcurrent and short circuit faults is paramount. High voltage ceramic tube fuses have emerged as a crucial solution, offering reliable protection across a diverse array of applications. These fuses are meticulously designed to ensure the safe operation of high voltage electrical systems, making them indispensable components in modern electrical engineering.

Formation Process

1. Material Preparation : Select high-quality insulating electrical steatite ceramic as the main raw material. This type of ceramic has excellent insulating properties, which is crucial for the performance of the high voltage fuse. It ensures that the ceramic tube can effectively prevent electrical leakage and maintain the safety of the electrical system.

2. Shaping : Utilize advanced molding techniques to shape the ceramic material into the desired tube form. The process is carefully controlled to ensure the uniformity and precision of the tube's dimensions. This is important because the shape and size of the ceramic tube directly affect the installation and compatibility with other components in the fuse assembly.

3. Firing : The shaped ceramic tubes are then subjected to high-temperature firing. This step is essential for strengthening the ceramic material and enhancing its mechanical and electrical properties. The firing process also helps to remove any impurities and improve the overall quality of the Ceramic Casing for Fuse Link.

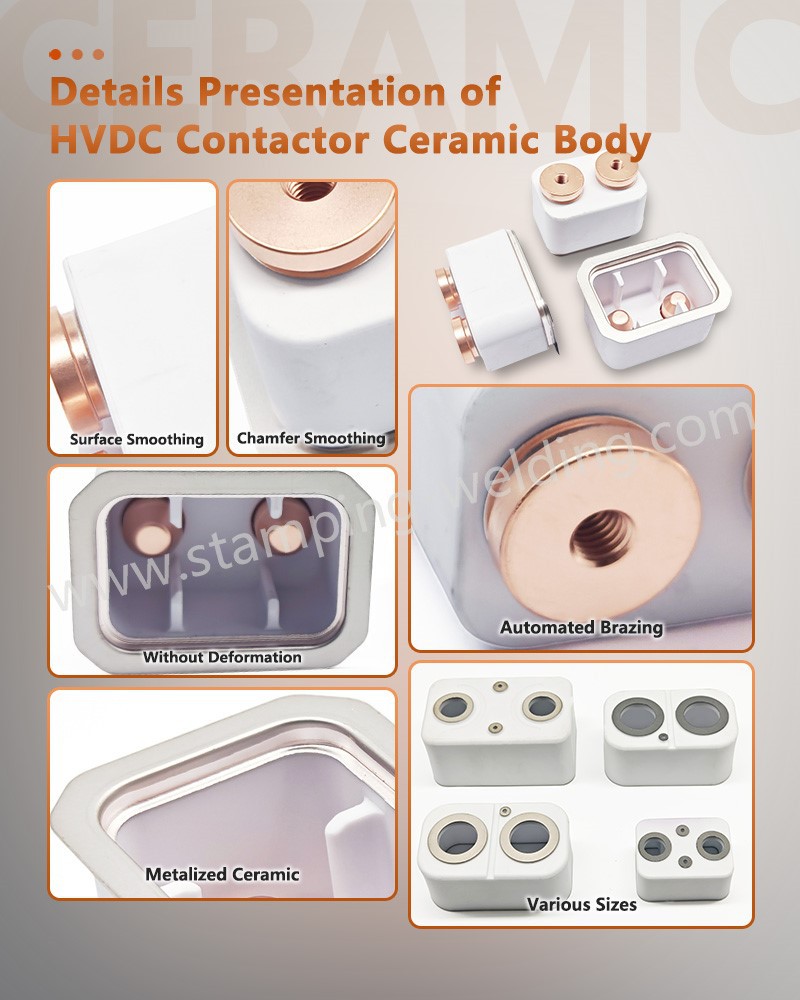

4. Surface Treatment : After firing, the ceramic tubes undergo surface treatment. This may include processes such as grinding and polishing to achieve a smooth surface finish. A smooth surface is beneficial for improving the electrical insulation performance and preventing the accumulation of dust other or contaminants that could potentially affect the fuse's performance.

Standard Configuration

1. Ceramic Tube : The core component of the high voltage fuse. It provides the necessary insulation and protection for the fuse link. The Ceramic Casing for Fuse Link is designed to withstand high voltage and electrical stress, ensuring the reliable operation of the fuse in various electrical systems.

2. Ceramic Casing for Fuse Link : This component is used to encase the fuse link. It is made from the same insulating electrical steatite ceramic material as the ceramic tube. The ceramic casing plays a vital role in protecting the fuse link from external factors such as moisture, dust, and mechanical damage.

3. Fusing Element : Typically made of metal materials, the fusing element is the part that melts and interrupts the electrical current when a fault occurs. The ceramic tube and ceramic casing work together to provide a stable and safe environment for the fusing element to operate.

4. End Caps and Terminals : These metal parts are used to connect the high voltage fuse to the electrical circuit. They are designed to ensure a secure and reliable electrical connection. We can produce all the metal parts required for relays, which means we have the capability to provide a complete set of components for the high voltage fuse assembly.

Type Summary

1. Standard Type : This is the basic type of ceramic tube. It is suitable for general electrical applications where standard voltage and current ratings are required. The standard type provides reliable protection against overcurrent and short circuit faults.

2. High Capacity Type : Designed for applications with higher current ratings. The high capacity type has a larger cross-sectional area of the fusing element and a more robust ceramic tube structure to handle the increased electrical load. It is ideal for use in electric and hybrid vehicle systems where high power and high voltage are common.

3. Customized Type : We offer customized solutions to meet specific customer requirements. The customized type can be tailored in terms of dimensions, voltage and current ratings, and other performance characteristics. This flexibility allows us to provide high voltage fuses that are perfectly suited to unique applications.

4. Special Application Type : For special environments or applications, such as high-altitude areas or extreme temperature conditions, we have developed the special application type. This type of ceramic tube for high voltage fuse has enhanced performance features to ensure reliable operation under challenging conditions.

Product features

1. Material and Quality : The ceramic tube is made from insulating electrical steatite ceramic, which is known for its excellent insulating properties, high mechanical strength, and thermal stability. TheCeramic Casing for Fuse Link is available in various dimensions to accommodate different fuse sizes and applications. The inner diameter, outer diameter, and length of the tube are precisely controlled during the manufacturing process. Detailed specifications, including voltage and current ratings, are clearly marked on the product for easy identification and. selection*

2. Performance Features : The ceramic tube provides superior insulation performance, effectively preventing electrical leakage and ensuring the safety of the electrical system. It also has good thermal conductivity, which helps to dissipate heat generated during the operation of the fuse. The ceramic material is resistant to aging and has a long service life, reducing the need for frequent replacement.

3. Compatibility and Integration : The ceramic tube for high voltage fuse is designed to be compatible with a wide range of electrical systems and components. It can be easily integrated into existing electrical circuits without the need for extensive modifications. The standardized design and configuration make it convenient for installation and maintenance.

contact us