Alumina Ceramic Parts Precision Machining — Industry Insight & Application Overview

Nov 10, 2025

In the realm of high-end manufacturing, Alumina ceramic parts precision machining has become a pivotal discipline - delivering engineering-grade components that merge exceptional material properties with intricate geometries. This article explores the foundations, processing challenges, production workflow, application domains and procurement considerations for Alumina Metallized Ceramics, aimed at engineering buyers and procurement professionals.

Material Origins & Structural Characteristics

Raw Materials & Formation – Alumina (Al₂O₃) ceramics originate from bauxite via the Bayer process, yielding high-purity aluminium oxide powder, which is then shaped (e.g., isostatic press, injection mold, extrusion) and sintered to form dense ceramic blanks.

Shrinkage & Densification – Following sintering in high-temperature furnaces, the ceramic undergoes dimensional shrinkage (commonly ~20%), meaning allowances must be designed in early stages.

Performance Profile – Fully sintered alumina features high hardness, excellent wear resistance, electrical insulation, thermal stability and chemical inertness - yet it remains brittle and requires specialist machining methods.

When you choose refurbished components via Precision Metallized Ceramics, you are selecting a material system designed for durability, precision and reliability.

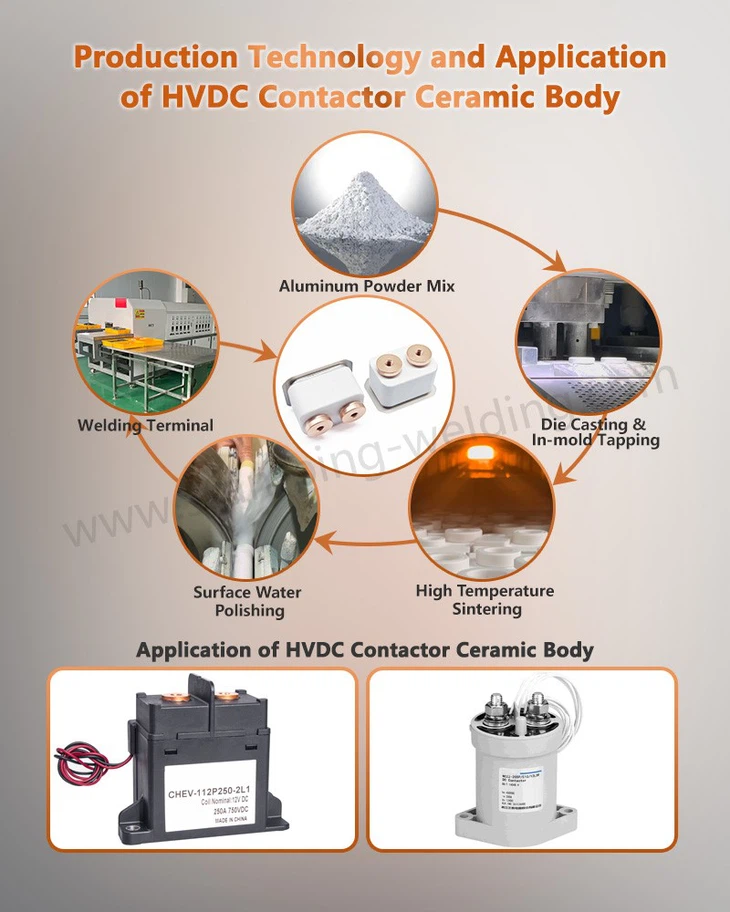

Production Workflow & Key Process Steps

Material Selection & Forming

Choose the appropriate aluminium oxide purity (e.g., 96 %, 99 %+), then form the green body using techniques like injection, pressing or extrusion.

Debinding, Pre-sinter & Sintering

After shaping, remove binders, then sinter under tightly controlled temperature and time profiles to achieve the required density and mechanical strength.

Pre-machining (Optional)

For complex parts, rough machining may be done in the green or semi-sintered state to reduce final finish machining load and minimise crack risk.

Precision Machining & Finishing

Use diamond-coated tools, CNC five-axis machines, grinding, polishing and possibly ultra-sonic or laser techniques to achieve tight tolerances and complex geometries via Metallized Alumina Ceramics for Electrical Components.

Surface Treatment, Inspection & Shipping

Finish operations can include polishing, laser marking or metallisation. Each part must pass dimensional checks, roughness inspection, electrical/chemical performance tests, then be packaged for shipment.

These steps ensure that Metallized Ceramic Insulating Tubes Metalizating Ceramic Part delivers components that meet strict engineering standards.

Application Domains & Industry Value

High-end Equipment Manufacturing

Used in pump/valve components, bearing sleeves, sliding parts, where the wear resistance, corrosion resistance and high-temperature stability of Metallized Ceramics for Electrical Components pay dividends.

Electronics & Semiconductor Systems

As insulating bases, precision positioning parts, guide rails or probe seats in clean-room and high-precision manufacturing, the technology of Metallized Ceramic Housing for Power Semiconductors becomes essential.

Chemical & Pharmaceutical Equipment

In environments with corrosive media and high-purity demands, the chemical inertness and stability of High-Strength Metallized Ceramic Components components make them ideal.

Aerospace & Energy Applications

In extreme environments (high temperature, shock, long-life reliability), the light-weight and durability advantages of Alumina Metallized Ceramics are leveraged.

Precision Instrumentation & Measurement

For sensor protection tubes, thermocouple holders, laser-device mounts where low thermal expansion, strong insulation and dimensional stability are required, Precision Metallized Ceramics stands out.

Through these application domains, the industry value of Metallized Alumina Ceramics for Electrical Components is clear: enhancing system reliability, extending life, reducing downtime and enabling design advancement.

Procurement Advice & Design Considerations

Material Grade & Specification

Define the required alumina purity and material state based on mechanical load, temperature, electrical or insulating demands - ensuring suitability for Alumina ceramic parts.

Manufacturer Capabilities

Verify the supplier's machining equipment (CNC 4/5-axis, diamond tooling, thin-wall & deep-hole expertise) and whether they have established capabilities in Metallized Ceramic Insulating Tubes Metalizating Ceramic Part.

Process Control & Quality Assurance

Ensure the provider employs a closed-loop process - from raw material to sintering, machining, surface finishing and inspection - to guarantee consistency in Metallized Ceramics for Electrical Components outcomes.

Design for Ceramic Behaviour

Account for sintering shrinkage, design allowances, support in clamping, minimise stress concentrations, and plan for possible hybrid interfaces when using Metallized Ceramic Housing for Power Semiconductors.

Total Cost of Ownership Focus

Although initial unit cost may be higher compared to metals or plastics, the longer lifespan, lower maintenance and improved system uptime offered by High-Strength Metallized Ceramic Components can deliver superior value over the equipment lifetime.

By following these procurement and design guidelines, you can harness the full potential of Alumina ceramic parts precision machining and ensure your engineering projects achieve optimal performance and reliability.

contact us